Concrete strengthened with graphene has been used in its first commercial project in a suspended floor slab at Manchester’s Mayfield regeneration scheme.

Concretene uses graphene to significantly improve the mechanical performance of concrete allowing for reductions in the amount of material used and the need for steel reinforcement.

At developer U+I’s Mayfield site it has been used to create a new 54x14metre mezzanine floor which will become a roller disco at the Escape to Freight Island attraction within Depot Mayfield.

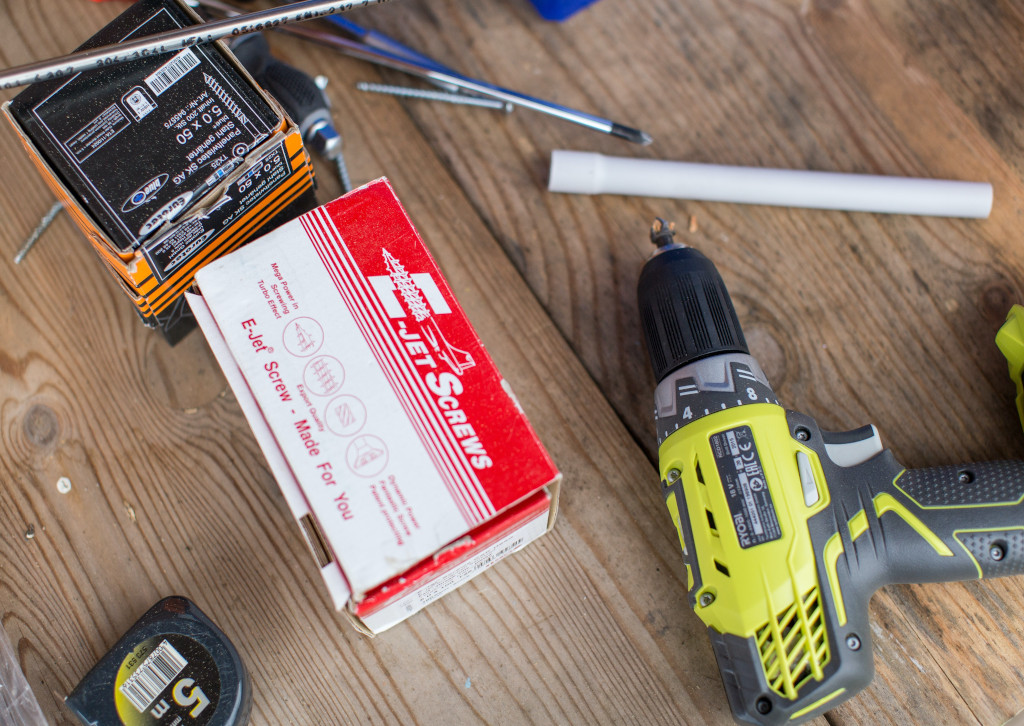

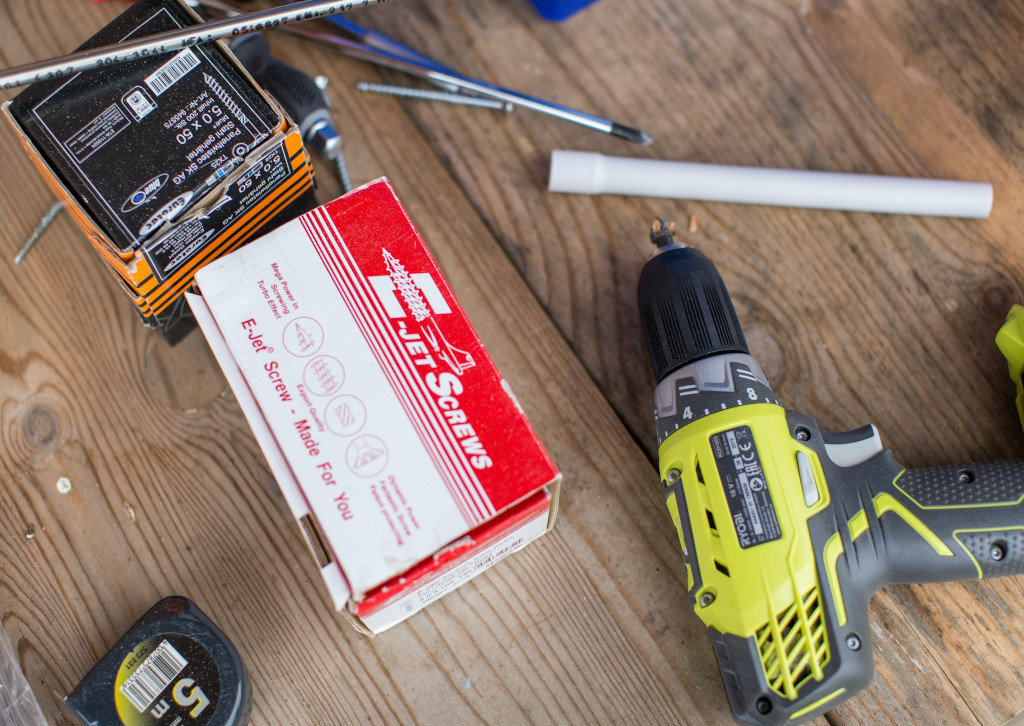

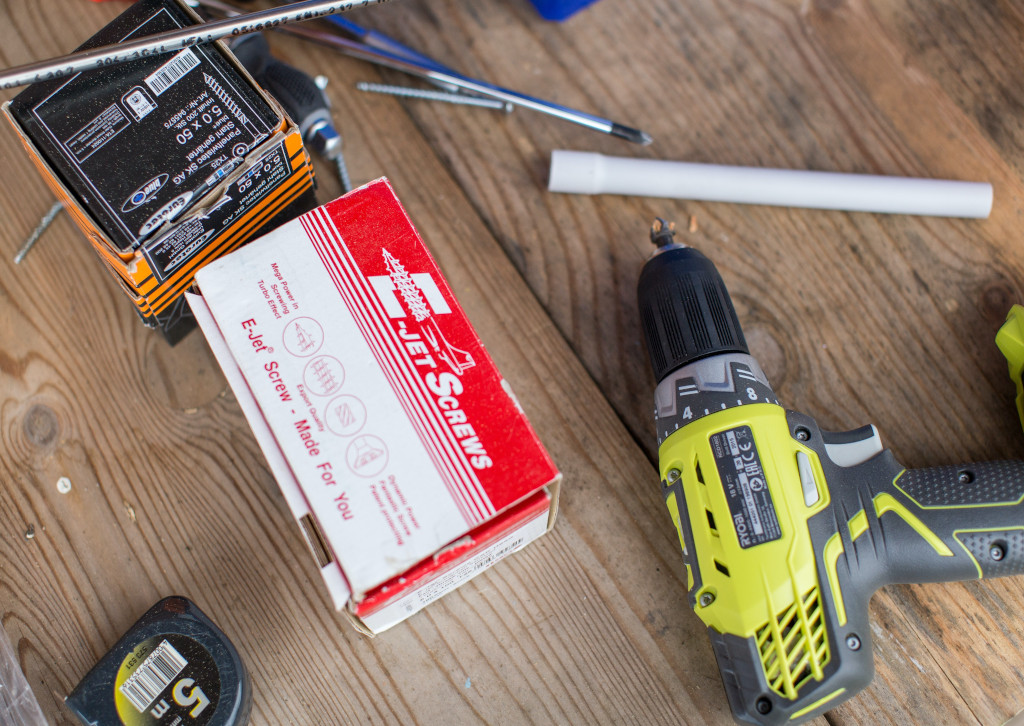

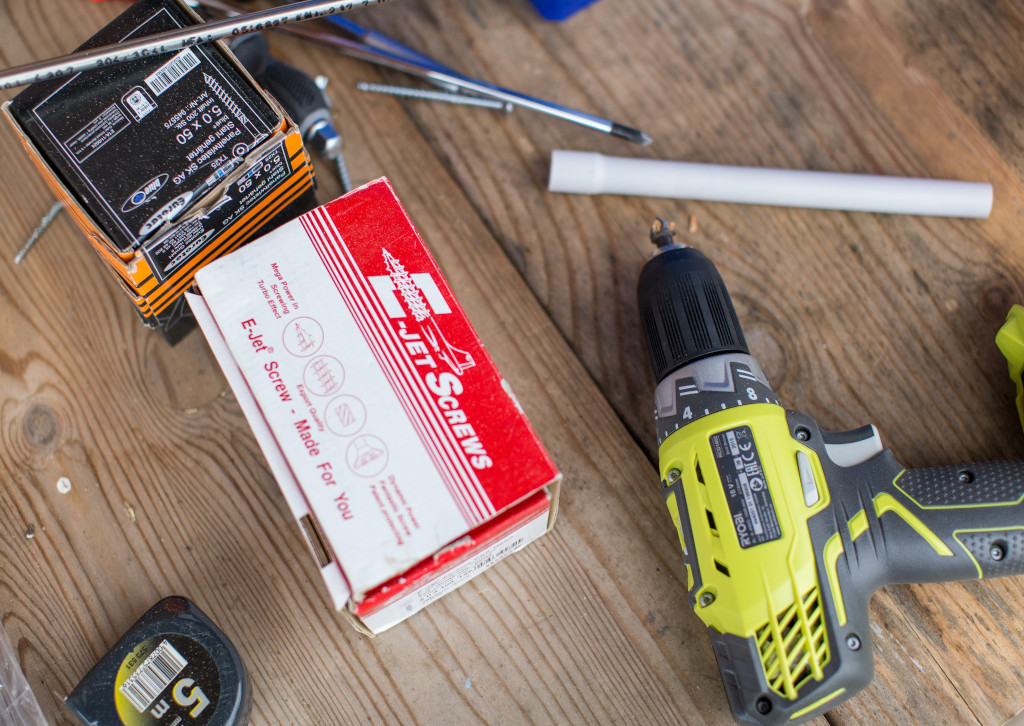

The Concretene pour overseen by Nationwide Engineering used the material developed by the University of Manchester’s Graphene Engineering Innovation Centre (GEIC).

Nationwide Engineering founder Alex McDermott said:Today is a huge milestone for the team, as not only is this our first commercial use of Concretene, but also the first suspended slab as used in high rise developments

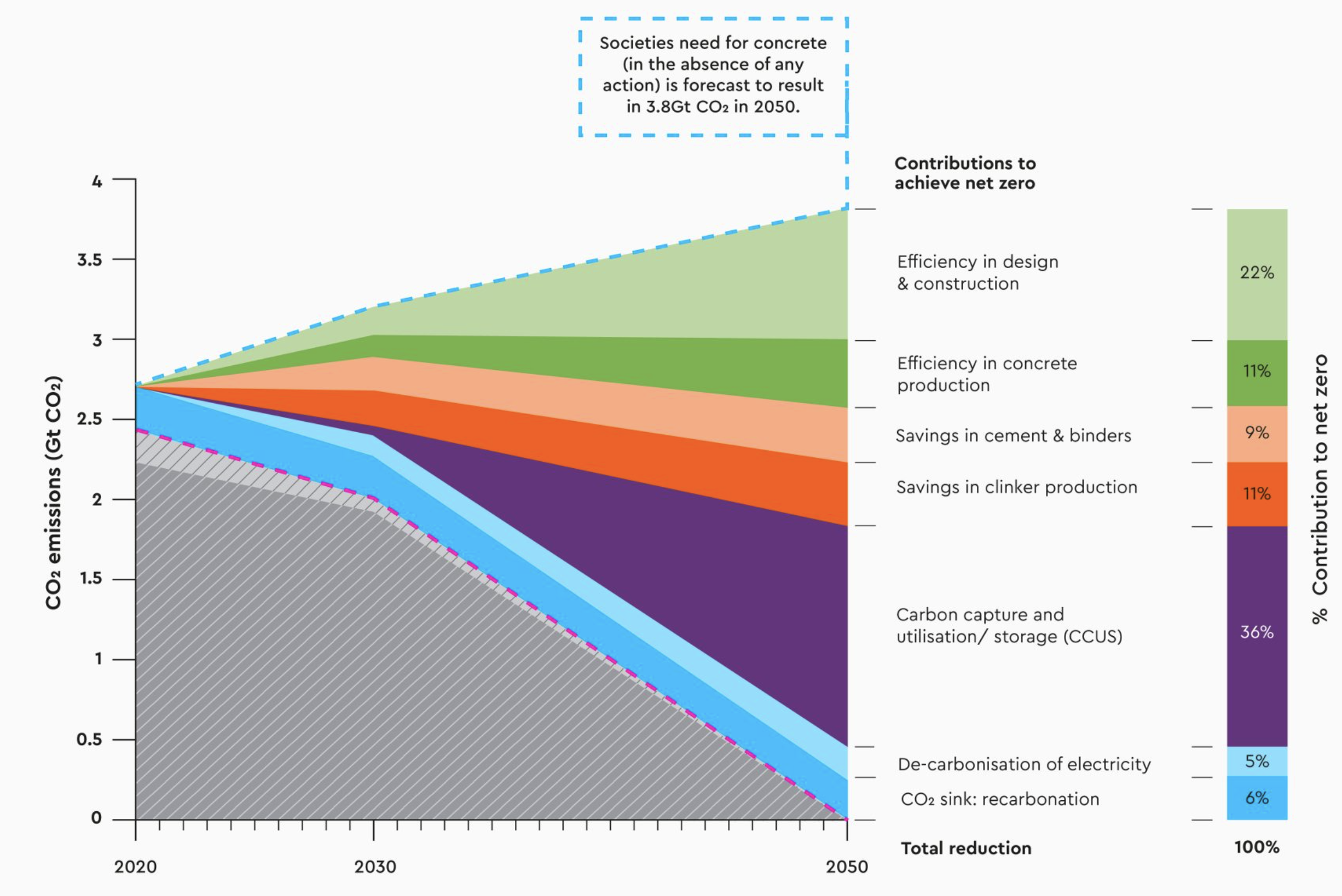

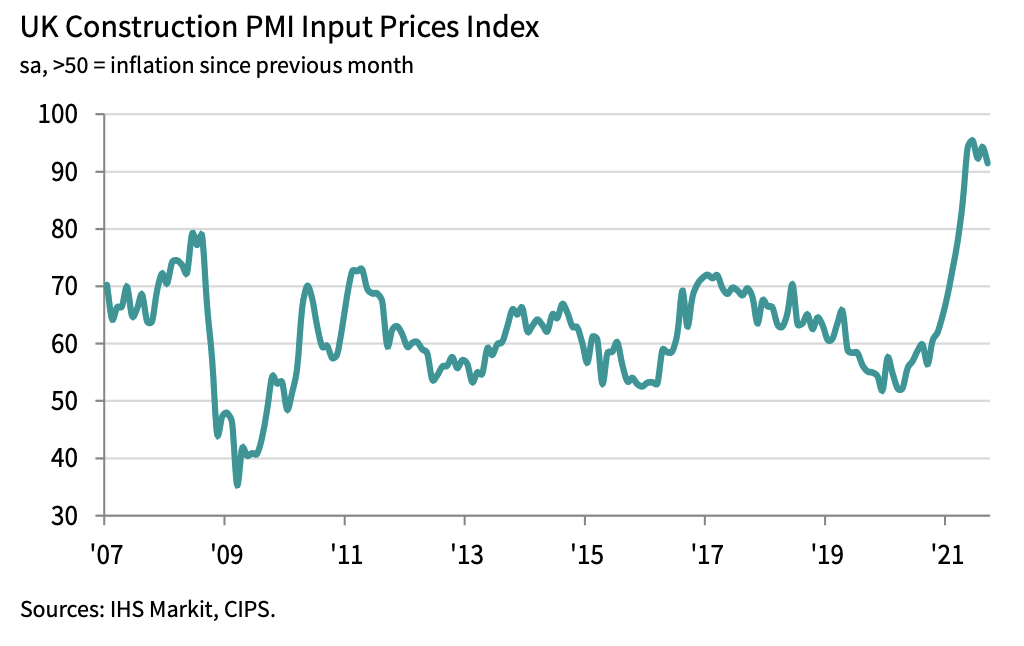

“As world leaders in Graphene Enhanced Concrete technology, the interest from the international building industry has been beyond expectations, as looming legislation is forcing significant carbon reductions throughout construction.

“Our partnership with the University has fast-tracked the development of Concretene, going from lab to product in 18 months.”

Concretene can reduce the amount of concrete required in construction projects by as much as 30% and also offers efficiency savings by slashing drying time from 28 days to just 12 hours.

Did you miss our previous article…

https://www.thegraduatemag.com/?p=801